Curtainwalls are common architectural features in commercial offices and complexes. These can be defined as framed wall-like structures that hang on the front of the building (like a curtain) and consist of glass, metal panels, or thin stones as spandrel fill-ins.

The main function for which the curtainwalls are created is to keep the outside weather out, thereby securing the occupants staying inside from any adverse influence of the weather conditions outside.

One of the other main features of the curtainwalls is that their framing is attached to the outside structure of the building and is not allowed to carry any structural load, including that of the roof or the floor of the building.

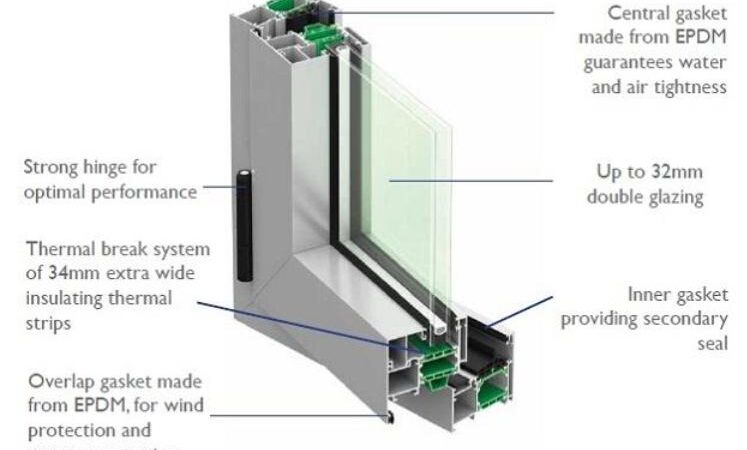

The other one is that some curtainwalls are thermally broken. This thermal break is created in order to make the windows, doors, and curtainwalls perform in a superior way to normal “cold” aluminium.

What is a Thermal Break in Commercial Doors,

Windows, and Curtainwalls?

The thermal break is a term used to define the break or the barrier that is built into commercial windows, doors, and curtain walling systems. These breaks popularly termed “thermal breaks”, are created between the face plate and the structural part of the mullion to shield the interior exterior part of the structure from the exterior weather outside.

The curtainwalls must be thermally broken for them to serve as a protective layer for the people inside.

Polyamide strips and why they are used for

curtainwalls

Polyamide strip is one of the most common materials used for years to create thermal breaks in curtainwalls, commercial windows, doors, and more. It is a reinforced polyamide strip, which occurs as a non-metallic, composite, structural material, and is installed between the interior and exterior profiles of the windows that forms an insulating barrier between the two.

Here are some of the prominent advantages of using polyamide strips as thermal barriers for commercial curtainwalls, windows, and doors:

- They provide a better thermal insulation

- They need lesser use of metals

- The polyamide strips are cost-effective

- They are easy to create thermal barriers with

- They help in resources to be conservedand can reduce operating costs

- They ensure maximum stability of the structure

- They are more than effective in resisting condensation

- They don’t require any special handling or fabrication

Polyamide is used for over 30-50 years to create strips that serve as thermal breaks. This is because of the low thermal conductivity that polyamide boasts of. Such a property helps polyamide reduce the transfer of heat and cold through the curtainwalls. The polyamide strips can also be coated with powder or anodised. All of these would further ensure that the curtainwalls are fit even to counter the harsh Australian weather, which includes fierce cyclones, damaging UV rays, regular corrosion, and more.

The wider the thermal break you will have, the better will the insulation be. Now, if you are wondering how to get the best curtainwalls for your region in Australia, all you have to do is contact Com-AL Windows. This is because being a trustworthy manufacturer, designer, and installer of commercial windows, doors, and curtainwalls, Com-Al Windows offers fitting products custom-made to your requirements.

Now that you know about polyamide thermal barriers and why they are used for curtainwalls, an obvious question might come to your mind, which is concerning the process of how polyamide strips are used for the same purpose. Yes, the next section will cover exactly that.

So let’s jump right into the process.

Into the Process How Polyamide Strips are used in

Curtainwalls!

Polyamide strips are largely considered a promising alternative to the polyurethane-based pour-and-debridge method. These strips are built as pre-extruded, structural plastic insulating structures made into strips that are usually reinforced with multidirectional glass fiber.

The curtainwalls that use polyamide strips have to be equipped with 2 separate aluminium extrusions, one for internal and the other to be used externally. Also, channels are created in the aluminium profiles, which helps to hold the polyamide strips together.

To maximise the shear strength of the assembly, these channels need to be bent, which results in the creation of teeth. These teeth of the channels also help in holding the polyamide strips and reduce any risks of shrinkage.

Now, as soon as the polyamide strips are inserted into the channel of the structure, the entire assembly is rolled. This helps create the bond, which makes the system a composite structure.

Getting your commercial windows, doors, and curtainwalls is now easier than ever with Com-AL Windows, a reputed commercial windows, doors, and curtainwalls supplier in Australia. Based in Perth, Western Australia, Com-AL Windows bring all the latest innovations and inventions in the world of commercial aluminium and glass windows and doors into reality. Besides, all of its products are tested in Australian labs and are able to withstand the Australian climate. So, what are you waiting for?

Components of a Thermally Broken Window System

Leave a Reply